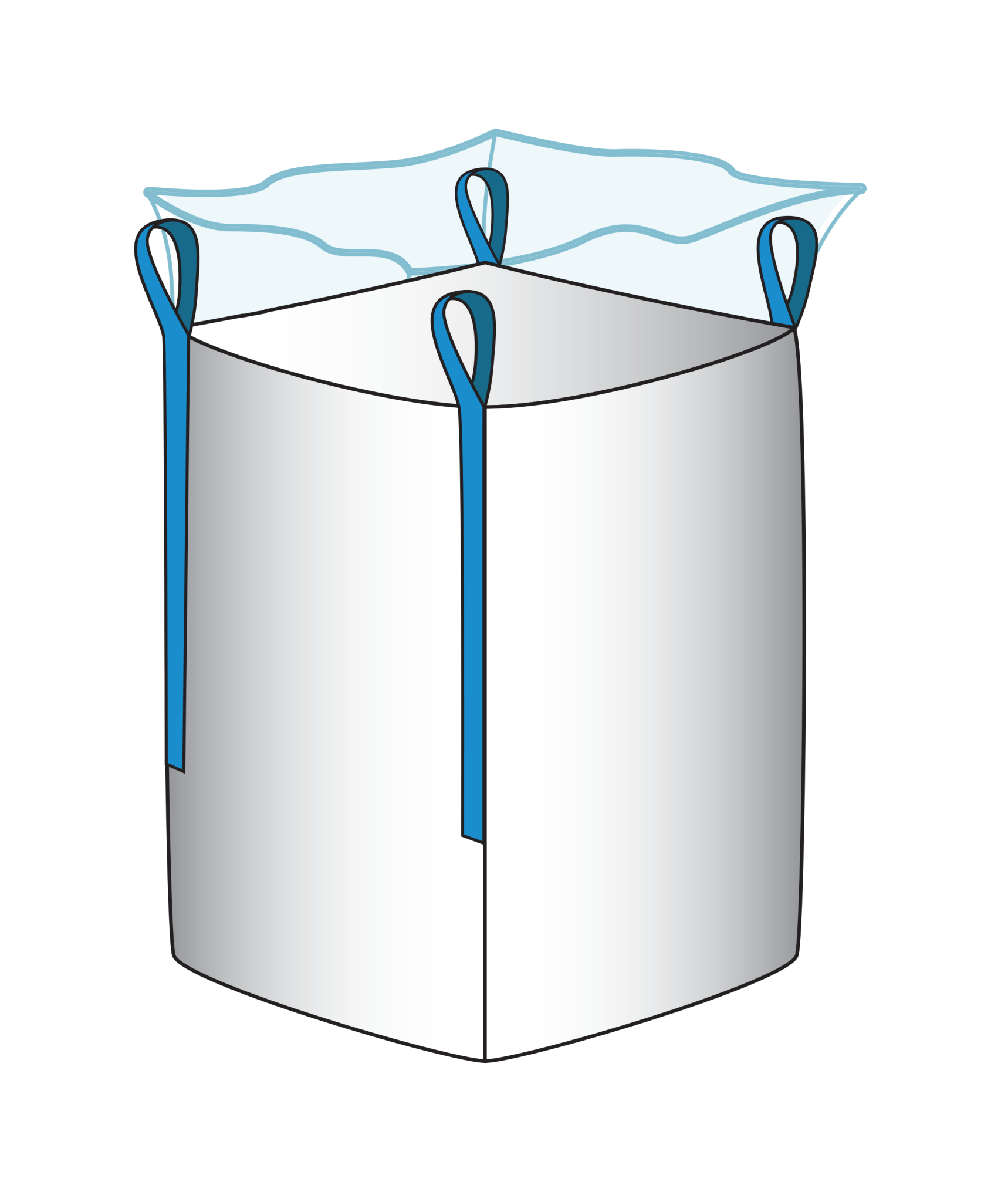

Bigbag with lnner Liner provides additional protection against environmental conditions and contamination. The lnner liner covers the inner side of the big bag so the filling product doesn't come into contact with the fabric or seams and avoid leaking. lnner liner can be in tubular form and bottle shaped.

lnner liner can be fixed in bigbag in 4 different way; Free lnserted, Glued (2 sides or 4 sides), 8 points tabbing and Sewn in side seams

| Construction | U-panel, 4 Side + Base |

| Clean Level | Industrial Clean, Food Grade |

| Safety Factor (SF) | 5:1 (Single Trip), 6:1 (Multi Trip) |

| Safety Working Load (SWL) | 200 kg to 2000 kg |

| Electrostatic Options | Type A (Standard), Type B (Antistatic), Type C (Conductive) |

| Sewing | Standard Sewing, Dust Proof (Optional) |

| Sewing Colour Options | White, Black, Blue, Green, Yellow, Red |

| Lift Style | 4 Side Seam Loops (4 Corner Loops), Cross Corner Loops |

| Loop Material | Monofilament, Multifilament |

| Loop Colour Options | White, Black, Blue, Green, Yellow, Red |

| Fabric | Flat Woven (Sulzer) Fabric, Circular Woven (Slitted) Fabric |

| Coating | Inside, Outside |

| Liner | Coex LDPE Liner, Gambo Liner (form Stable) |

| Printing | Optional |